Table of content

FIRE SAFETY FOR SEATING – A QUESTION OF COMPOSITION

B1 – A WELL-KNOWN STANDARD, BUT NOT ALWAYS THE RIGHT ONE

COMPOSITE TEST CLASSIFIED

AS PER DIN 66084 – A SUITABLE

TESTING PROCEDURE FOR FURNITURE IN GERMANY

EN, BS, CAL, ETC. – AN OVERVIEW

OFTHE MOST COMMON

INTERNATIONALFIRE SAFETY

STANDARDS

EXCURSUS: AN OVERVIEW OF THE SURFACE TREATMENT PROCEDURE

FIRE SAFETY AT INTERSTUHL – A COMPREHENSIVE ISSUE

GLOBAL FIRE SAFETY IN THE

INTERIOR DESIGN SECTOR –

BACKGROUND, STANDARDS

INTRODUCTION

Fire safety is highly relevant in many industries. However, there

have always been ambiguities and uncertainties around this

topic. We have taken a closer look at fire safety, including the

various relevant international standards and testing procedures,

in order to provide some clarity. At the heart of this topic

is the frequently cited and required B1 certification. What

criteria does it require to be met? To what sectors does B1 certification apply?

Fire safety is vital, especially in areas where large numbers of

people are present. Accordingly, it is large companies and public

facilities, such as offices and airports, where the most care

needs to be taken to ensure fire safety. Entrances, waiting areas

and corridors are particularly relevant in this context, since

these areas are also used as emergency routes.

Above all, fire safety is a preventative measure. A fire can be

a life or death situation - so it is essential to prevent one from

arising. To this end, both construction measures and furnishings

can play an important role. Ideally, no fires should occur

at all; however, if a fire occurs, it should not spread, or should

spread extremely slowly, producing as little smoke as possible.

Just 10 kilograms of flexible foam can produce 20,000 m3 of

dangerous fire smoke1 - 95% of the approximately 500 people

killed by fires in Germany every year die as a result of suffocation

caused by the highly toxic gases contained in fire smoke2.

It is therefore important that the planning phase takes into

account the fire safety properties of furnishings and materials

in order to select and use the best options.

Fire safety is vital, particularly as a preventative measure and especially in areas where large numbers of people are present. It is therefore important to take fire safety requirements into consideration at an early stage, during the planning phase.

1 Dr. Otto Widetschek

2 Bundesverband Brandschutz-Fachbetriebe e.V.

FIRE SAFETY FOR SEATING – A QUESTION OF COMPOSITION

Conventional seating and upholstered furnishings are not well suited for safe use, as the materials they contain are usually combustible. However, modifications can be made to the composition of different materials in order to comply with various standards. This aims3 to ensure that the furnitureConventional seating and upholstered furnishings are not well suited for safe use, as the materials they contain are usually combustible. However, modifications can be made to the composition of different materials in order to comply with various standards. This aims3 to ensure that the furniture

- does not represent an ignition source on its own – i.e. it cannot spontaneously ignite,

- will extinguish by itself,

- generates little fire smoke

- and will not accelerate the spread of a fire that has arisen.

One challenge this poses is how to provide fire-safe furnishings

without having to compromise on comfort and design.

The fire safety requirements that apply to furnishings are set out in a number of laws and regulations and are continuously

updated and expanded. The most important regulations,

which architects, building owners and operators in Germany

must observe, are

- the German Ordinance on Meeting Places,

- state building codes,

- hospital building regulations

- and the "Fire loads in emergency routes" expert recommendation from the AGBF Bund.

Ensuring that furniture is fire-safe is less about the individual materials that are used and much more about the combination of all materials used in the production of the furniture. Regulations such as the German Ordinance on Meeting Places and state building codes regulate fire safety requirements for objects with which architects, building owners and operators in Germany must comply.

3 EN1021 Part 1 & 2

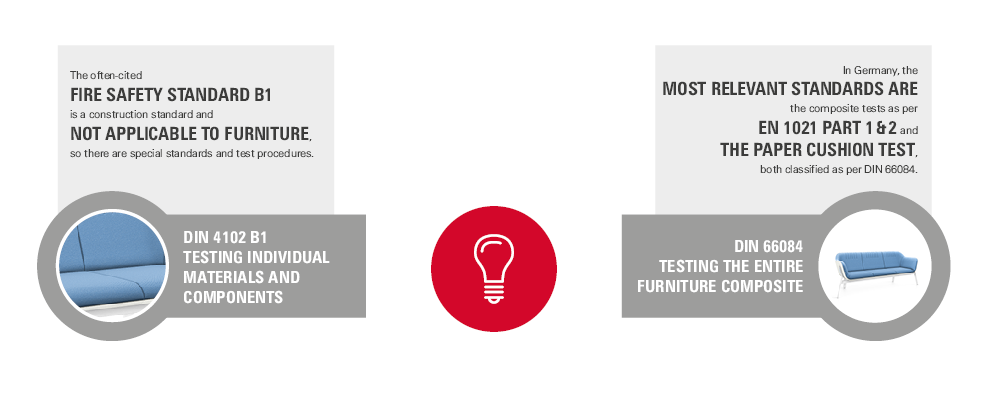

B1 – A WELL-KNOWN STANDARD, BUT NOT ALWAYS THE RIGHT ONE

The B1 standard in accordance with DIN 4102 categorises the

flame-retardant fire behaviour of building materials and components.

The DIN standard is a construction standard and is primarily

intended to apply to building materials such as insulation,

coatings and pipes. At this point, a distinction is made between

different fire rating classifications.

Non-combustible materials belong to FIRE RATING CLASS A.

These are classified as:

A1 – NON-COMBUSTIBLE:

- without organic components

- without combustible components

A2 – NON-COMBUSTIBLE:

- with organic components

- may contain combustible components

FIRE RATING CLASS B comprises combustible materials, which are classified as:

- B1: flame-retardant building materials

- B2: normally flammable building materials

- B3: easily flammable building materials

According to DIN 4102-01 B1, the fire rating

is tested by exposing the material to flames from eight burner

nozzles in a vertical shaft. During this test, flat specimens are

exposed to flame for ten minutes in order to test the flame

retardancy of the material. Furniture cannot be tested in this

way because of its size.

But how can this be the case when many tenders and construction

projects stipulate that the furniture used must be B1

certified? Of course, one might assume that if an item of furniture

is made up entirely of B1 certified materials, the resulting

composite would be categorised in fire safety class B1. However,

this does not take into account any potential interactions

between materials or the fire behaviour of the item as a whole.

Testing and certification in accordance with B1 requires a distance

of at least 40 mm from other flat materials4, which is

rarely the case with materials and upholstery composites, if at

all. In this respect, upholstered furniture is considered to be

"single items of furniture" and therefore not within the scope

of the B1 building material standard.

DIN standard B1 is a construction standard; it classifies the flame retardancy of building materials individually, but not of material combinations such as those found in furniture. This means that furniture cannot comply with the B1 standard.

4 DIN 4102 B1

COMPOSITE TEST CLASSIFIED

AS PER DIN 66084 – A SUITABLE

TESTING PROCEDURE FOR FURNITURE IN GERMANY

Since the construction standard for materials cannot be applied to items of furniture, special testing procedures and standards apply here. These differ by country and scope of application. In Germany, the most relevant standards are the composite tests as per EN 1021 Part 1 & 2 and the paper cushion test, both classified as per DIN 66084. The aim of these standards is to establish application-specific, risk-appropriate classifications for upholstery composites. These are intended to provide the best possible protection against fires caused deliberately or through negligence, and to minimise the risk of ignition. The test is performed in three steps:

PAPER CUSHION TEST:

- Test in accordance with DIN 66084 class P-a

- A paper cushion (100 g) is burned on the test specimen

- Flames must extinguish independently within 15 minutes

- Flame height must not exceed 45 cm above the backrest and must not reach the edges of the seat

MATCH TEST/ GAS FLAME:

- Test in accordance with EN 1021 Part 2 (classification in accordance with DIN 66084 P-b)

- A gas flame equivalent to a match is applied to the specimen

- Flames must extinguish independently within 2 minutes after the match is removed

- Smouldering fire is permitted to spread no more than 100 mm from the ignition source

CIGARETTE TEST:

- Test in accordance with EN 1021 Part 1 (classification in accordance with DIN 66084 P-c)

- A burning cigarette is placed on the test specimen

- It must not be burning or smouldering after 60 minutes have passed

EN, BS, CAL, ETC. – AN OVERVIEW

OFTHE MOST COMMON

INTERNATIONALFIRE SAFETY

STANDARDS

There are a number of different international standards and tests regarding the fire behaviour of furniture and intended to ensure fire safety. European standards (EN standards), for instance, apply in all EU member states, while national standards such as German industry standards (DIN standards) (e.g. DIN 66084 for upholstery composites) only apply within Germany. EU standard EN 13501 is often cited and stipulated; it combines a range of international testing procedures for building products and types. However, like the B1 standard in Germany, it is not suitable for material composites and is therefore not used to classify furniture that has an upholstery composite. The information below sets out a range of international standards and categorises the classification for which the different standards apply (building material/type vs. upholstery composite).

European Union

EN 13501 "Single-burning item":

- Combines all vertical fire behaviour tests

- Contains a wide variety of classes and combinations

In addition to fire behaviour, the side effects of fire are also taken into consideration here:

- Fire behaviour (classes A–F)

- Smoke development (classes s1–s3)

- Flaming droplets/particles (classes d0–d2)

- Construction standard: Building products/types

EN 1021 Part 1 & 2 is an upholstery composite test (for further details, see section 4)

- Test in accordance with EN 1021 Part 1 = cigarette test

- Test in accordance with EN 1021 Part 2 = match test/gas flame

- Upholstery composite test

United Kingdom

BS EN1021-1

BS EN1021-2

BS 5852 Part II Crib 5/Crib 7:

- Similar to DIN 66084 P-a; instead of a paper cushion, a standardised pile of wood (crib) with fire accelerant is used

- Classification in accordance with BS 7176 Low Hazard

- Upholstery composite test

Austria

ÖNORM B 3825:

- Flame application using a butane gas burner

- Independent classification (flame-retardant, normally flammable, easily flammable)

- Upholstery composite test

France, Belgium, Luxembourg

NF P 92 503-507:

- Flame applied to a specimen using a small burner and electric fire – the duration of the afterburn and the destroyed surface are assessed

- Classification according to M1–M4

- Construction standard, also classifies upholstery composites

NFD 60-013 (AM18 regulation)

- Flame applied to the surface using a propane gas burner equivalent to a 20 g paper cushion

- Upholstery composite test

Italy

UNI 9175 – 1IM:

- Burner is held at the join between the seat and backrest

- Flame is held in this position for a specific length of time, three times: Results classified in 3 classes (1IM, 2IM, 3IM) (positive result after 20, 80, 140 seconds)

- Upholstery composite test

USA, Canada

California TB117:

- Cigarette test performed on the entire upholstery composite (see section 4: DIN 66084)

International

IMO A.652:

- Comparable with EN 1021-1&2 Cigarette and gas flame test (see section 4: DIN 66084)

- Upholstery composite test

| BUILDING MATERIALS/ COMPONENTS | UPHOLSTERED FURNITURE | ||

|---|---|---|---|

|

EU |

EN 13501 | EN1021-1 & 2 | |

|

DE |

N 13501 + DIN 4102 | EN1021-1 & 2 + DIN 66084 |

|

| GB | EN1021-1 & 2 + BS 5852 Crib 5 / Crib 7 |

|

|

|

CH |

EN1021-1 & 2 | |

|

| F, B, L | NF P 92 (F, B, L) | EN1021-1 & 2 NF D 60-013 |

|

| USA | CAL TB 117 | |

|

| IT | UNI 9175 | |

| Cigarette test In accordance with EN 1021 Part 1 | |

Match test/gas flame In accordance with EN 1021 Part 2 | |

Paper cushion test In accordance with DIN 66084 P-a | |

Paper cushion test Simulation using gas flame | Testing procedure using a stack of wood (Crib 5/7) |

A number of different standards and testing procedures are in force internationally; these can be divided into standards that apply in multiple countries (e.g. "EN" at the EU level) and country-specific standards, such as "DIN" (Deutsche Industrie Norm) German industry standards. It is also important to differentiate between different types of tests and classification: Some standards, such as EN 13501 only relate to individual building products/types and are unsuitable for furniture. Others test upholstery composites and thereby categorise furniture.

EXCURSUS: AN OVERVIEW OF THE SURFACE TREATMENT PROCEDURE

In general, surfaces such as upholstery can be treated in two

ways:

a) Anchoring down to the fibre for a long-lasting effect. Incorporating

a flame-resistant yarn can ensure compliance with B1

certification. This method is most effective and often lasts for

the entire service life of the material, but takes time and effort.

b) Subsequent impregnation by treating the surface. This

effective treatment process is performed on the finished

material and requires less time and effort than anchoring.

Depending on the objective, this method is suitable for achieving

flame-resistance according to a range of classifications or

antimicrobial treatment on available surfaces.

Anchoring down to the fibre or subsequent impregnation: The type of surface treatment used is heavily dependent on the materials to be treated/the materials in use and the targeted effectiveness.

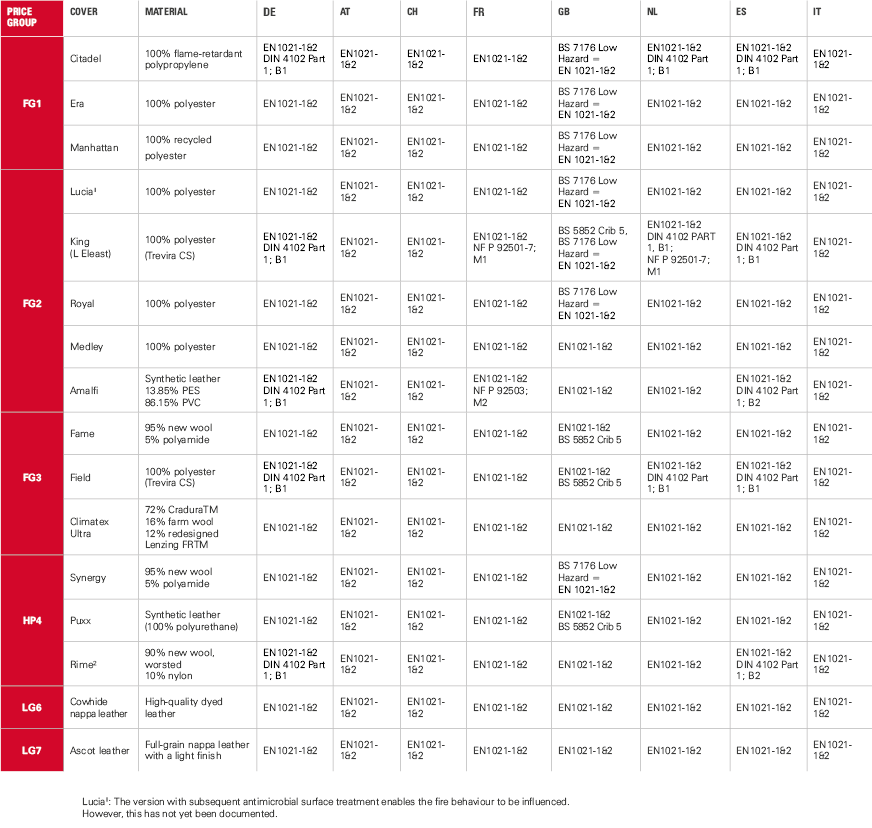

FIRE SAFETY AT INTERSTUHL – A COMPREHENSIVE ISSUE

To deal with the topic of fire safety comprehensively and from

an international perspective, almost all of our products comply

with European standard EN 1021 (classified in accordance with

German industry standard DIN 66084 P-b and P-c) as standard.

On request, we can also meet additional international standards,

such as P-a classification in accordance with DIN 66084 or

BS 5852 (Crib 5 and Crib 7). We are able to do this thanks to the

use of flame-retardant materials in accordance with DIN 4102-B1

combined with a flame-retardant CMHR(Combustion Modified High Resilient) foam or a flame liner (non-combustible glass fabric). The materials required to be fire safe are anchored

directly in the fibres or applied to the surface later, depending

on the material and targeted effectiveness.

To meet important international fire safety requirements, Interstuhl meets a range of standards, including European standard EN1021-1&2 and classification P-b and P-c in German standard DIN 66084, as standard. On request, we can also comply with additional international standards – whatever you need.

SUMMARY AND CONCLUSION

Fire safety is vital, particularly as a protective measure and especially

in areas where large numbers of people are present.

It is therefore important to take fire safety requirements into

consideration at an early stage, during the planning phase.

Ensuring that furniture is fire-safe is less about the individual

materials that are used and much more about the combination

of all materials used in the production of the furniture. Regulations

such as the German Ordinance on Meeting Places and

state building codes regulate fire safety requirements for objects

with which architects, building owners and operators in

Germany must comply.

DIN standard B1 is a construction standard; it classifies the

flame retardancy of building materials individually, but not of

material combinations such as those found in furniture. This

means that furniture cannot comply with the B1 standard.

A number of different standards and testing procedures are in

force internationally; these can be divided into standards that

apply in multiple countries (e.g. "EN" at the EU level) and country-

specific standards, such as "DIN" (Deutsche Industrie Norm)

German industry standards.

Interstuhl Büromöbel GmbH & Co. KG

Brühlstraße 21

72469 Meßstetten-Tieringen

interstuhl.com

Ernst Walter

Tel.: +49 7436 871 – 335

Mail: e.walter@interstuhl.de

FAQS

Can I have furniture tested in accordance with DIN 4102-1 B1?

No. Only individual materials used in the furniture can be tested. However, when combined, these can exhibit interactions – as a result, entire items of furniture cannot be B1 certified.

What is the right fire safety standard for furniture in Germany?

In Germany, composite tests, classified in accordance with DIN 66084 and other standards (e.g. EN 1201), are the correct standards to use when assessing the fire safety of furniture.

Which fire safety standards are important for the international furniture industry?

On an international scale, there are a wide range of standards that apply to specific countries or regions. EN1021-1&2, for instance, applies throughout the European Union and is the standard used for furniture. Contact us directly to discuss your individual requirements – we'll be happy to find the right solution for you.

Can I have products produced to meet my own requirements and in compliance with certain certifications?

In principle, every product can be adapted. Please contact us so that we can assess how best to meet your needs.

Who should I contact at Interstuhl regarding my questions about fire safety and individual product requirements?

Please contact us by e-mail at e.walter@interstuhl.de or by phone at +49 (0) 7436 871 335. We will respond to you as soon as we can to deal with your enquiry.

1020

1020Undersøgelse